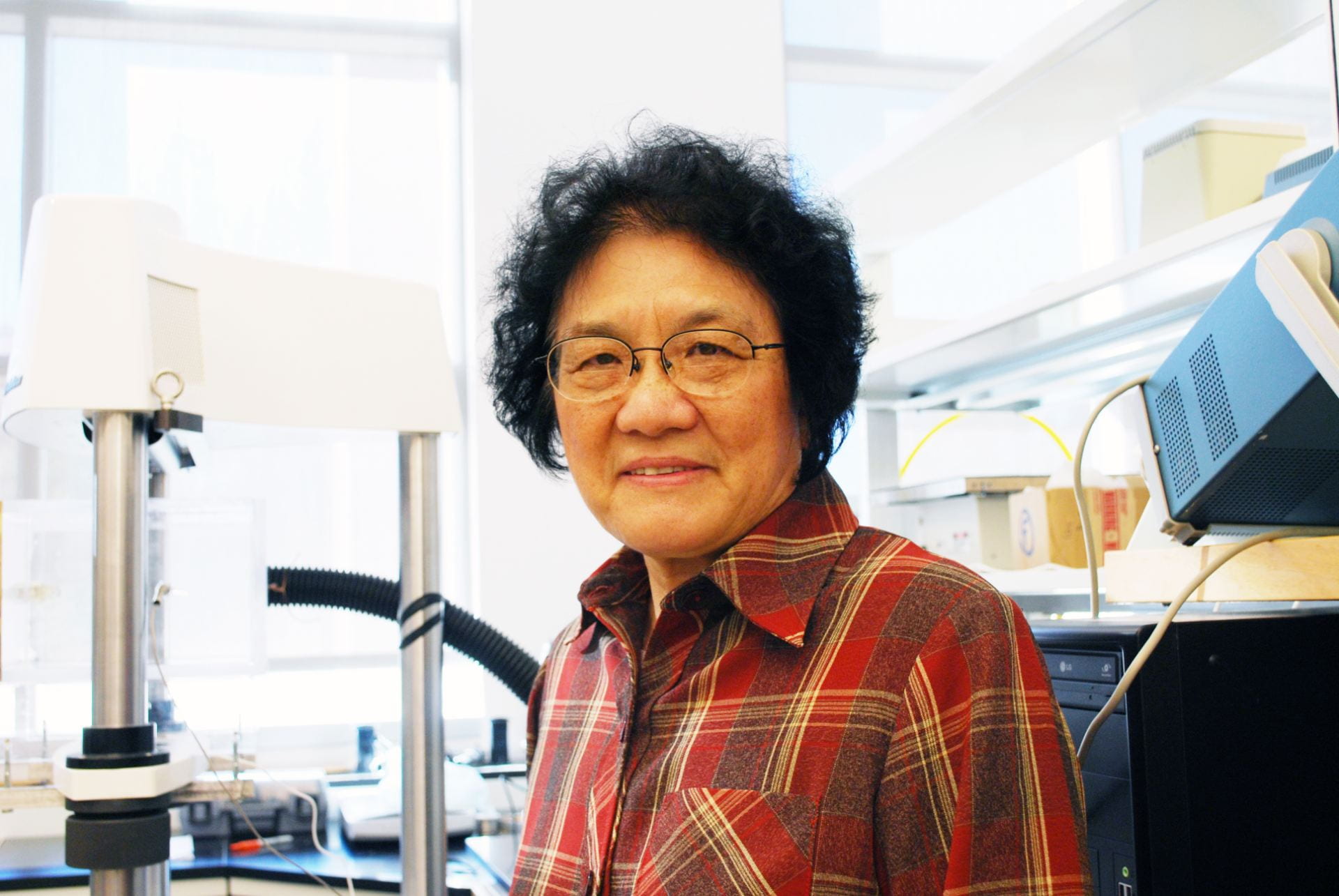

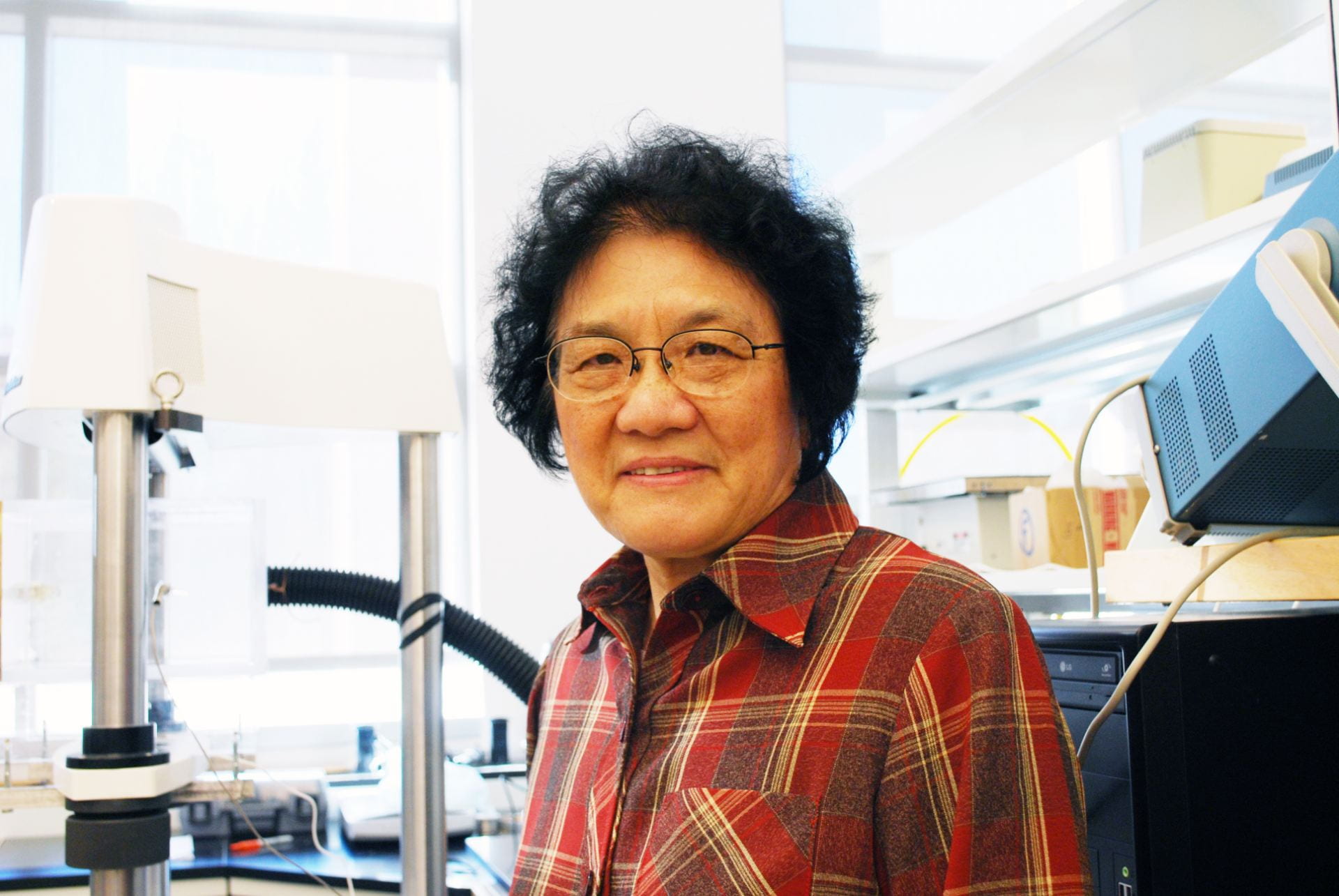

Dr. Rong Gan has received the George Lynn Cross Research Professorship, the highest research and creative activity honor given by the University to a faculty member who has demonstrated outstanding leadership over a period of years in his or her field of learning or creative activity. Join us in honoring Dr. Gan for this remarkable achievement!

Dr. Gan came to OU in 1999 after serving as the Director of Biomedical Engineering at Hough Ear Institute in Oklahoma City and has been a part of AME since. She says this is because of her strong foundation here at AME. She has a “good connection with the Health Science Center and the Norman Campus.” Dr. Gan said she also has a lot of support here from her mentors, the University, and the “excellent students.”

“No matter what kind of student, no matter their background,” Dr. Gan says, “you have to pay attention to them and guide them.” You have to, “know how to mentor them because they are so important to research.” Dr. Gan wants students to be motivated for their future because the future is, “totally in their hands.”

Dr. Gan says the George Lynn Cross Research Professorship is a huge recognition of accomplishment for her research and education, two things, Dr. Gan says, “are connected and can’t be separated.” She says researchers must-have, “100% confidence in their original area, but have to look for a new direction because there must be innovation to solve the problem.” Dr. Gan’s advice for researchers is to seek innovation, collaboration, and for them to publish their work. She says for people to, “always keep good motivation and to work hard,” for the benefit of future generations.

See the article below for more information about Dr. Gan’s research and awards:

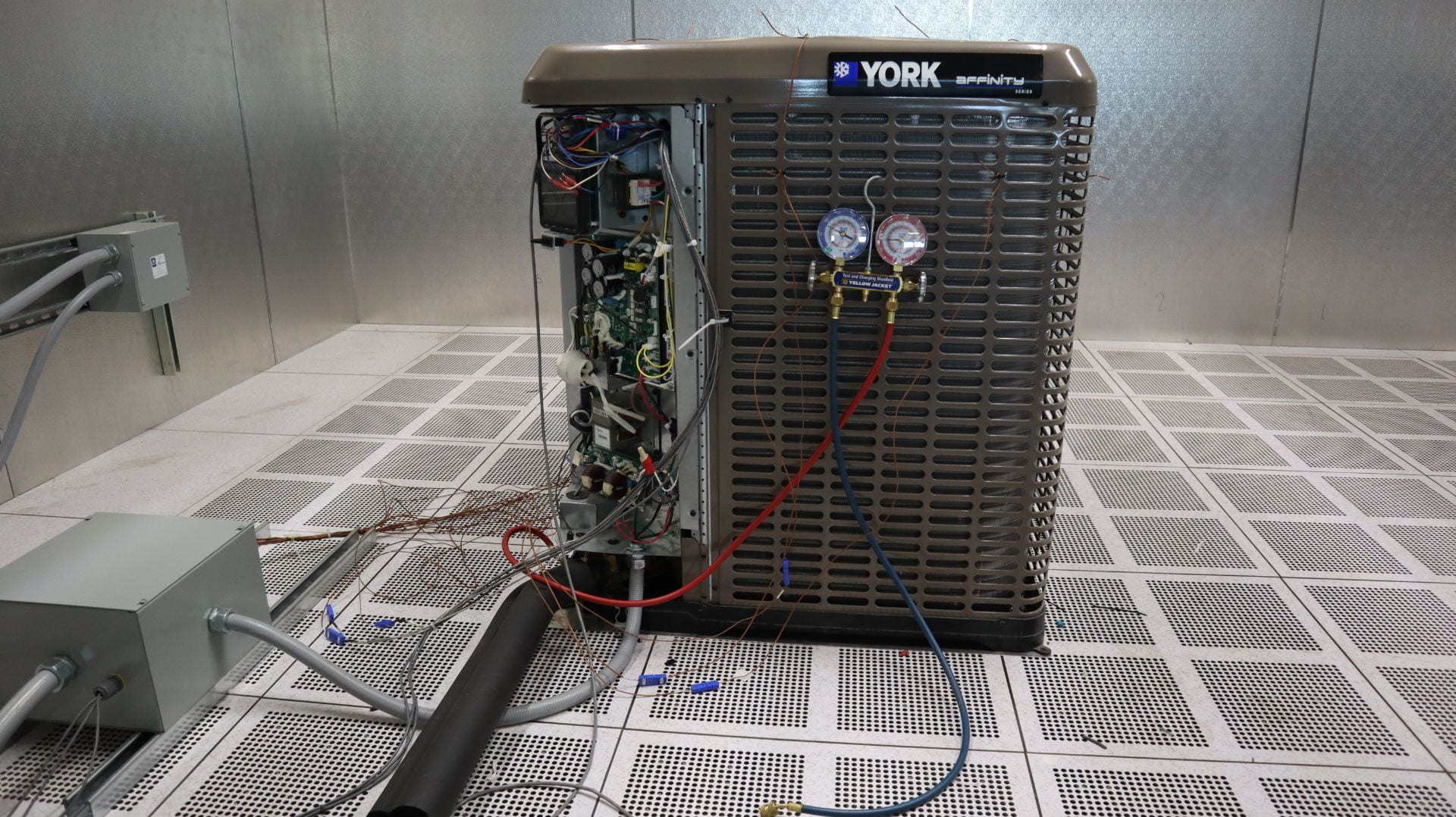

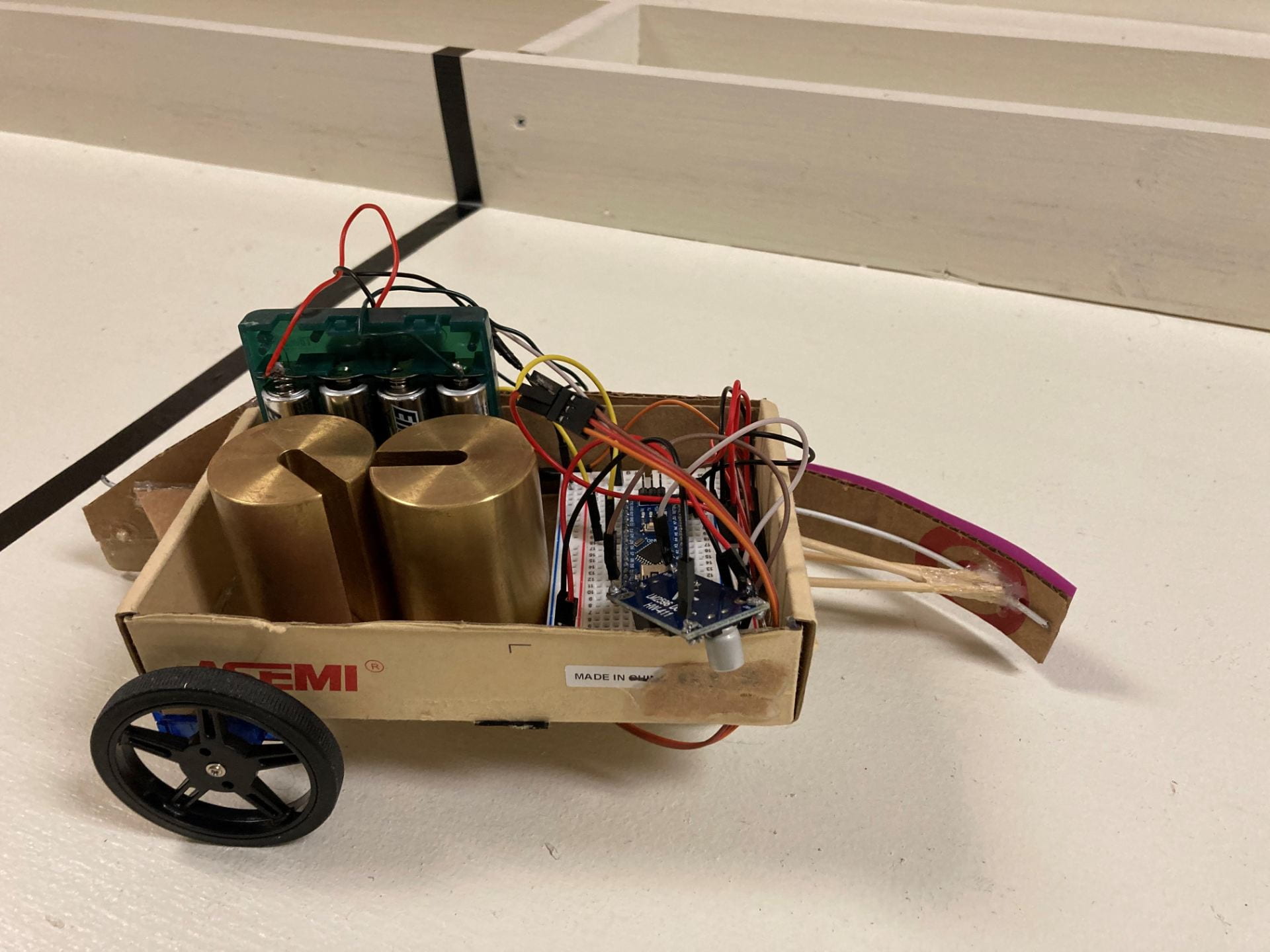

With her strong background in biomechanics and implantable devices, Dr. Gan has developed a truly transformational, well-funded research program at OU in Biomechanics for Protection and Restoration of Hearing, including implantable hearing devices, dynamic properties of ear tissues, auditory function tests, and computational modeling of sound and blast wave transmission through the ear.

As PI for all of her funded research projects, Dr. Gan has built an exceptionally strong research group that simultaneously conducts physical experiments in animals and human cadavers as well as foundational 3D computational modeling of human and animal ears.

The ability to carry out all these research activities covering both basic and applied research, instrumentation, data acquisition, theoretical modeling, and device design and testing in one lab is Dr. Gan’s research strength. She uses biomechanics systems approaches as fundamental methods with the goal to develop innovative technologies for measuring sound or blast wave transmission through the ear and the 3D physics-based computational model of the human ear for an understanding of hearing and protection mechanisms, improving diagnosis of middle ear diseases, and serving as a tool for the design and evaluation of implantable hearing devices and hearing protection devices.

Dr. Gan’s research work has been mainly funded by highly competitive grants from Federal and State government agencies such as the DOD, NIH, NSF, OCAST, and the Whitaker Foundation. Particularly in recent years, Dr. Gan’s research activities have been extended into new areas of biomechanical modeling and measurement of blast injury and hearing protection mechanisms for U.S. military priority research. This innovative development is based on original concepts of normal sound transmission through the ear and stimulated by Dr. Gan’s scholarship in the areas of measurements in human cadaver and animal ears and the finite element modeling of sound transmission through the ear.

Dr. Gan’s research has resulted in numerous publications and led to breakthroughs in implantable devices, computational modeling, and therapeutics for hearing restoration with 4 patents (two pending approval). She is a world-class researcher, a truly exceptional scholar, and among the very best educators we have at the University of Oklahoma. Her research has a direct impact on human health in terms of restoring hearing and improving the quality of life for the 38 million Americans with hearing impairment and providing hearing protection for military personnel. The George Lynn Cross Research Professorship award is a recognition of her superb research productivity and remarkable contributions to biomedical engineering research and education at the University of Oklahoma.

Click here to find the Norman Campus Faculty Tribute Award article written about Dr. Gan.