We are very happy to welcome five new faculty members to the AME family.

Iman Ghamarian (Materials)

Dr. Ghamarian was a postdoctoral fellow at the University of Michigan before joining OU. He received his Ph.D. from Iowa State University in 2017, M.S. from the University of North Texas in 2012, and B.S. from the Sharif University of Technology in 2010, all in Materials Science and Engineering. His cross-disciplinary research activities have focused on understanding and engineering the forward and backward relationships between processing, microstructures, and mechanical properties in high-performance structural alloys. To explore these relationships, he integrates advanced characterization techniques with data analytics approaches and physical metallurgy principles. Dr. Ghamarian has more than 30 publications about developing structural alloys in peer-reviewed journals, including several papers in Acta Materialia and Physical Review Letters. He was one of two recipients of the college of engineering Master/Doctoral Fellowship award.

Dr. Ghamarian was a postdoctoral fellow at the University of Michigan before joining OU. He received his Ph.D. from Iowa State University in 2017, M.S. from the University of North Texas in 2012, and B.S. from the Sharif University of Technology in 2010, all in Materials Science and Engineering. His cross-disciplinary research activities have focused on understanding and engineering the forward and backward relationships between processing, microstructures, and mechanical properties in high-performance structural alloys. To explore these relationships, he integrates advanced characterization techniques with data analytics approaches and physical metallurgy principles. Dr. Ghamarian has more than 30 publications about developing structural alloys in peer-reviewed journals, including several papers in Acta Materialia and Physical Review Letters. He was one of two recipients of the college of engineering Master/Doctoral Fellowship award.

Erkan Kayacan (Unmanned Systems)

Dr. Kayacan will be joining us in Spring 2022 from the School of Mechanical and Mining Engineering at the University of Queensland (UQ), Australia where he is currently an Assistant Professor in Mechatronics. He received his Ph.D. degree from the University of Leuven (KU Leuven), Belgium. Prior to UQ, he was a Postdoctoral Researcher with the Delft University of Technology, the University of Illinois at Urbana-Champaign, and the Massachusetts Institute of Technology. His research interests center around control theory, artificial intelligence, and real- time optimization, with a particular emphasis on foundational theory and the experimental realization of robotic and autonomous systems. Dr Kayacan is a recipient of the Best Systems Paper Award at Robotics: Science and Systems (RSS) in 2018.

Dr. Hiroshi Ozawa comes to AME from Japan, where he was an Associate Professor in the Department of Aeronautics and Astronautics at Tokyo Metropolitan University (TMU). He received his Ph.D in 2010 in the Department of Aerospace Engineering from Nagoya University under the supervision of Prof. Dr. Yoshiaki Nakamura. From 2010 to 2013, he was a Postdoctoral scholar under the supervision of Prof. Dr. Klaus Hannemann at DLR, head of Spacecraft Department, Göttingen. Since 2013, he has been a faculty member at TMU. His research interests lie in the experimental high-speed aerothermodynamics using high-speed wind tunnels with optical flow diagnostics.

Dr. Hiroshi Ozawa comes to AME from Japan, where he was an Associate Professor in the Department of Aeronautics and Astronautics at Tokyo Metropolitan University (TMU). He received his Ph.D in 2010 in the Department of Aerospace Engineering from Nagoya University under the supervision of Prof. Dr. Yoshiaki Nakamura. From 2010 to 2013, he was a Postdoctoral scholar under the supervision of Prof. Dr. Klaus Hannemann at DLR, head of Spacecraft Department, Göttingen. Since 2013, he has been a faculty member at TMU. His research interests lie in the experimental high-speed aerothermodynamics using high-speed wind tunnels with optical flow diagnostics.

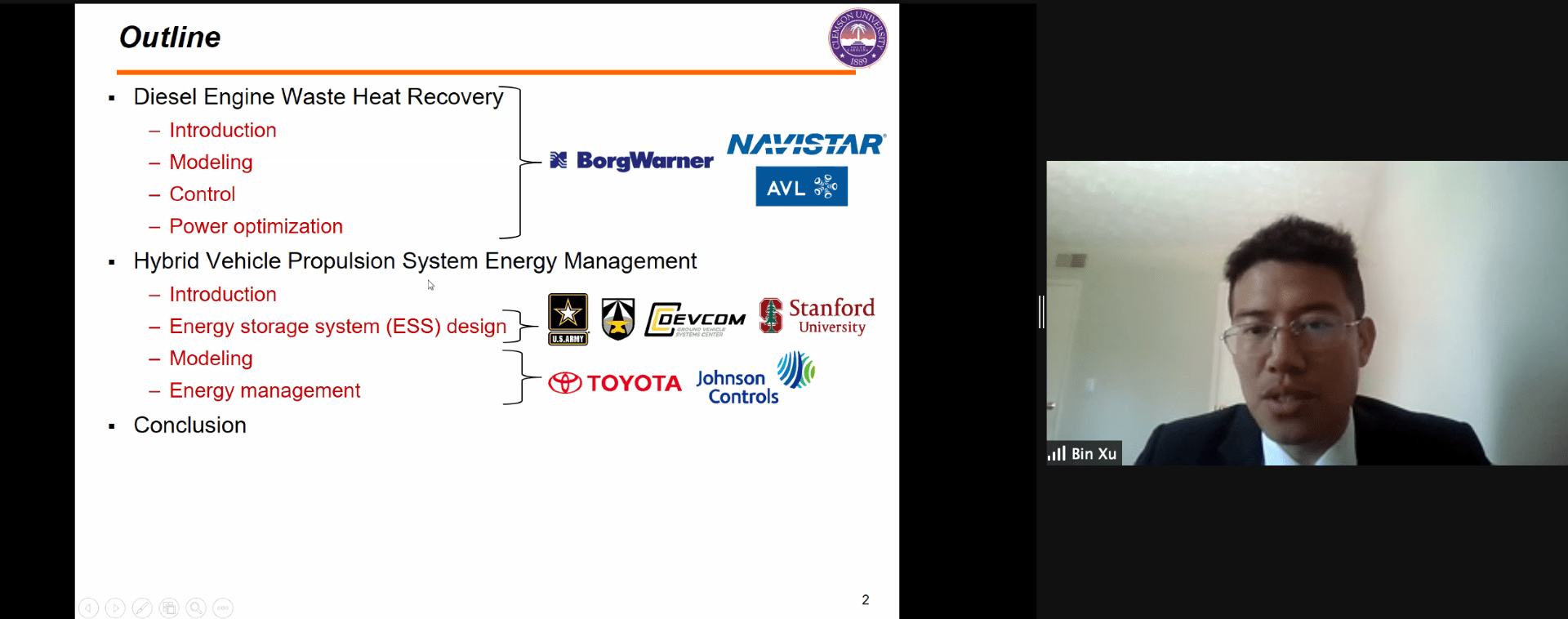

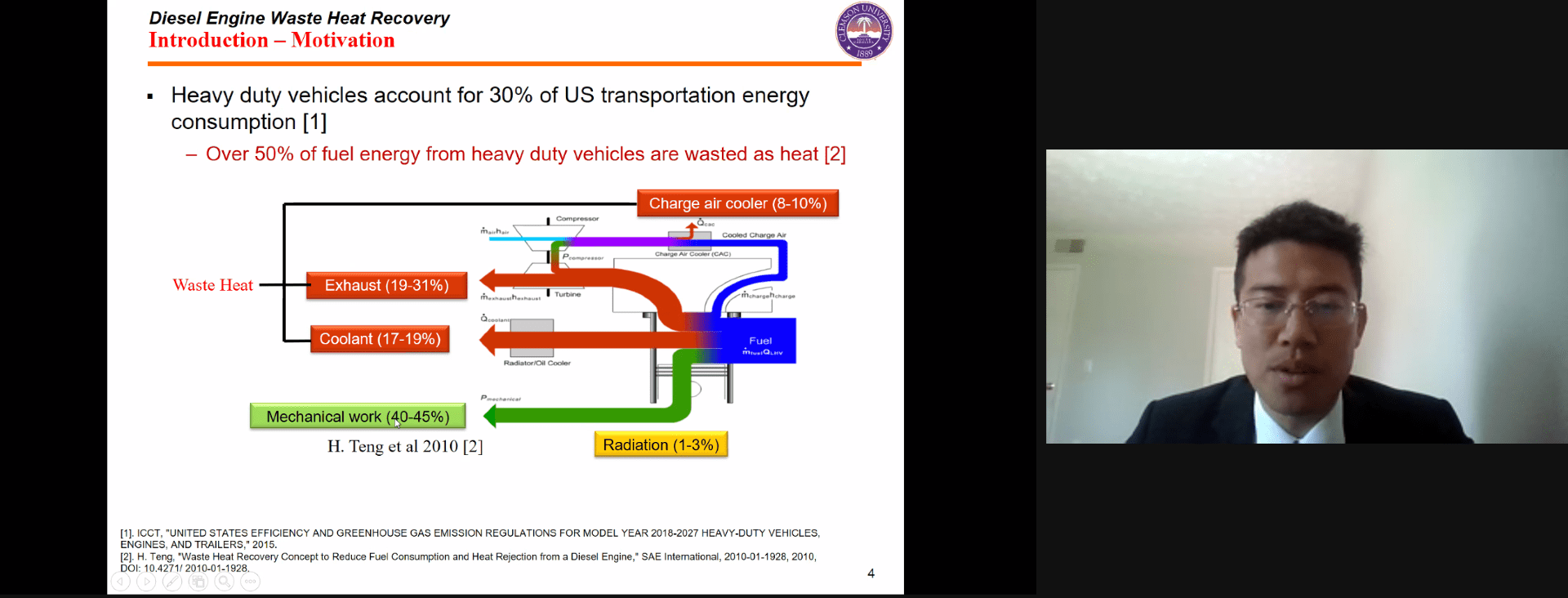

Bin Xu (Propulsion)

Dr. Bin Xu joins us from the Department of Automotive Engineering, Clemson University, where he has been serving as a Research Assistant Professor since March 2020. Prior to that, Dr. Xu was a Research Scientist at the Stanford University. Dr. Xu received his B.S. degree from Hunan University China in 2013, Ph.D. from Clemson University in 2017, both in Automotive Engineering. Dr. Xu’s research focus on propulsion system modeling and control, particularly in the areas of physics-based and data-driven modeling, control, and fuel efficiency optimization. Over the past 4 years, Dr. Xu has published 31 peer-reviewed articles including 13 first-authored journal articles and his research have been cited 337 times in Google Scholar. Dr. Xu is the Guest Editor of SAE International Journal of Electrified Vehicles and a Review Editor of Frontiers in Energy Research. Additionally, Dr. Xu serves as the reviewer for 10+ journals in energy and transportation fields, such as Renewable and Sustainable Energy Reviews, Applied Energy, and IEEE Transactions on Intelligent Transportation Systems.

Dr. Bin Xu joins us from the Department of Automotive Engineering, Clemson University, where he has been serving as a Research Assistant Professor since March 2020. Prior to that, Dr. Xu was a Research Scientist at the Stanford University. Dr. Xu received his B.S. degree from Hunan University China in 2013, Ph.D. from Clemson University in 2017, both in Automotive Engineering. Dr. Xu’s research focus on propulsion system modeling and control, particularly in the areas of physics-based and data-driven modeling, control, and fuel efficiency optimization. Over the past 4 years, Dr. Xu has published 31 peer-reviewed articles including 13 first-authored journal articles and his research have been cited 337 times in Google Scholar. Dr. Xu is the Guest Editor of SAE International Journal of Electrified Vehicles and a Review Editor of Frontiers in Energy Research. Additionally, Dr. Xu serves as the reviewer for 10+ journals in energy and transportation fields, such as Renewable and Sustainable Energy Reviews, Applied Energy, and IEEE Transactions on Intelligent Transportation Systems.

Dong Zhang (Sustainable Energy)

Dr. Dong Zhang is currently a Postdoctoral Research Associate with the Department of Mechanical Engineering at Carnegie Mellon University, Pittsburgh, PA, USA. He received his Ph.D. and M.S. degrees from the University of California at Berkeley, Berkeley, CA, USA, in 2020 and 2016, respectively, all in systems and control engineering. He also earned his B.S. degree from the University of Michigan, Ann Arbor, MI, USA, in 2015, in Civil and Environmental Engineering. He was also awarded a double B.S. degree in Electrical and Computer Engineering from Shanghai Jiao Tong University, Shanghai, China, in 2015. His current research interests include dynamical system estimation and controls, optimization, machine learning, renewable energy systems, energy storage, and advanced Lithium-Ion battery management systems. Dr. Zhang is a recipient of the American Society of Mechanical Engineers (ASME) Energy System Best Paper Award at 2020 American Control Conference (ACC) and 2020 Dynamic Systems and Control Conference (DSCC), and the UC Berkeley College of Engineering Block Grant Fellowship.

Dr. Dong Zhang is currently a Postdoctoral Research Associate with the Department of Mechanical Engineering at Carnegie Mellon University, Pittsburgh, PA, USA. He received his Ph.D. and M.S. degrees from the University of California at Berkeley, Berkeley, CA, USA, in 2020 and 2016, respectively, all in systems and control engineering. He also earned his B.S. degree from the University of Michigan, Ann Arbor, MI, USA, in 2015, in Civil and Environmental Engineering. He was also awarded a double B.S. degree in Electrical and Computer Engineering from Shanghai Jiao Tong University, Shanghai, China, in 2015. His current research interests include dynamical system estimation and controls, optimization, machine learning, renewable energy systems, energy storage, and advanced Lithium-Ion battery management systems. Dr. Zhang is a recipient of the American Society of Mechanical Engineers (ASME) Energy System Best Paper Award at 2020 American Control Conference (ACC) and 2020 Dynamic Systems and Control Conference (DSCC), and the UC Berkeley College of Engineering Block Grant Fellowship.

We are very excited to welcome these new members of our team, and wish each of them success in the years ahead!